|

Hardenable metals for blades |

|

Hardenable metals for blades |

|

Color of bullets indicates it is listed/sold by:

| |

Admiral STEEL

Admiral STEEL K & G Finishing Supplies

K & G Finishing Supplies  Jantz Supply

Jantz Supply |

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply  Texas Knifemaker's Supply

Texas Knifemaker's Supply |

AEBL

AEBL

Seems to be about the same as 440-B. Extremely easy to grind, heat

treats like 440-C. Very easy to buff and polish, but is reported to have

'several quirky' habits in grinding that makes it difficult to use on larger

or thicker knives. No enough chromium to form chromium carbides.

Very good choice for miniatures, kitchen knives etc. It does not hold edge

very good, but is easier to sharpen with a honing steel.

AEB-L(Bohler-Uddeholm) - Udderholm Steel - Sweeden.

Proprietary Equivalents:

Hitachi - PS-60 & PS60, Lone Wolf - LV-02, Outokumpu - SF.100, Sandvik - FC61 & FC-61, 13C26

Originally designed for making razor blades.

Typical Analysis

| Carbon | Manganese | Chromium | Silicone | Phosphorus | Sulfur |

| 0.67 | 0.60 | 13 | 0.40 | 0.025 | 0.015 |

AISI A-2, A-2 FM

AISI A-2, A-2 FM

Color marking

A-2: Ends with Red stripe, and White and Red stripe full

length.

A-2 FM: Ends White and gold, with White and Gold stripe full

length.

This is anAir Hardening steel containing 5% Chromium. It is deeper

hardening an more wear-resistant than AISI O-1, and holds a keener cutting

edge. It is more readily machined than high carbon, high chromium grades.

Where even greater machinability is desired, A-2 FM should be specified.

Its outstanding toughness makes it a frequent choice for combat knives.

Used by Chris Reeve and Phil Hartsfield, Blackjack made a few models from A-2.

Typical Analysis

| Carbon | Manganese | Chromium | Molybdenum | Vanadium |

| 1 | 0.60 | 5.25 | 1.10 | 0.25 |

| 1/16" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6"

1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6" |

| 3/32" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6"

1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6" 1" 1-1/2" 1" 1-1/2" |

| 1/8" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6" 7" 8"

10" 12"

1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6" 7" 8"

10" 12" 1" 1-1/2" 1" 1-1/2" |

| 5/32" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6" 7" 8"

10" 12" 14" 15"

1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6" 7" 8"

10" 12" 14" 15" 1" 1-1/2" 1" 1-1/2" |

| 3/16" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6" 7" 8"

10" 12"

1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6" 7" 8"

10" 12"  1" 1-1/2" 1" 1-1/2" |

| 1/4" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6" 7" 8"

10" 12"

1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4" 2"

2-1/2" 3" 3-1/2" 4" 5" 6" 7" 8"

10" 12" 1" 1-1/2" 2" 1" 1-1/2" 2" |

| 5/16" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4"

2"

1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4"

2" |

| Length |

18" amp;

18" amp;  36"

36" |

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply Jantz Supply

Jantz Supply  Admiral STEEL

Admiral STEEL

AISI D-2 (AIRDI® 150) TOOL STEEL

AISI D-2 (AIRDI® 150) TOOL STEEL

Typical Analysis

| Carbon | Chromium | Vanadium | Manganese | Molybdenum | Silicon | |

| D-2 | 1.55% | 11.50% | 0.90% | 0.35% | 0.80% | 0.45% |

| 154-CM | 1.03% | 13.75% | 0% | 0.25% | 3.50% | 0.41% |

| Carbon + | Chromium + | Vanadium + | + Nickel | + Tungsten | All others |

| 1.67% | 12.27% | 1.13% | 0.27% | 0.25% | same |

| °F | As hardened | 400 | 500 | 98% | 700 | 800 | 900 | 1000 |

| Hardness(Rc) | 62-64 | 60-62 | 59-61 | 58-60 | 57-59 | 57-59 | 57-59 | 54-56 |

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply K & G Finishing Supplies

K & G Finishing Supplies Jantz Supply

Jantz Supply  Texas Knifemaker's Supply

Texas Knifemaker's Supply Admiral STEEL

Admiral STEEL

AISI O-1, O-2

AISI O-1, O-2

Color Marking

O-1: Ends Aluminum, and Aluminum stripe full length.

O-2: Ends Yellow and Pink, with Yellow and Pink stripe full

length.

O-1 and O-2 are the most widely used general purpose oil hardening tool

and die steels. They are used where it is desirable to maintain minimum

distortion and dimensional change, and at the same time have a good

combination of hardness and toughness. Machining characteristics of these

grades are very good.

O-1 steel very popular with forgers as is easy to work with, and relatively cheap to buy.

It takes and holds an edge superbly, and is very tough, but rusts easily.

Used by Randall Knives.

Typical Analysis

| Carbon | Manganese | Chromium | Tungsten | Vanadium | |

| O-1 | 0.90 | 1.20 | 0.50 | 0.50 | 0.20 |

| O-2 | 0.90 | 1.60 | 0 | 0 | 0 |

| PG 1/64" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"

3" 4"

1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"

3" 4" |

| PG 1/32" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"

3" 4" 5" 6"

1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"

3" 4" 5" 6" |

| PG 3/64" |  1/4" 5/16" 3/8" 1/2" 3/4" 1" 1-1/4"

1-1/2" 2" 2-1/2" 3" 4" 5" 6"

1/4" 5/16" 3/8" 1/2" 3/4" 1" 1-1/4"

1-1/2" 2" 2-1/2" 3" 4" 5" 6" |

| PG 1/16" |  1/4" 5/16" 3/8" 1/2" 3/4" 1" 1-1/4"

1-1/2" 1-3/4" 2" 2-1/2" 3" 4" 5" 6"

8" 10"

1/4" 5/16" 3/8" 1/2" 3/4" 1" 1-1/4"

1-1/2" 1-3/4" 2" 2-1/2" 3" 4" 5" 6"

8" 10" |

| PG 5/64" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"

3" 3-1/2" 4"

1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"

3" 3-1/2" 4" |

| PG 3/32" |  1/4" 5/16" 3/8" 1/2" 3/4" 1" 1-1/4"

1-1/2" 2" 2-1/2" 3" 4" 5" 6" 8"

10"

1/4" 5/16" 3/8" 1/2" 3/4" 1" 1-1/4"

1-1/2" 2" 2-1/2" 3" 4" 5" 6" 8"

10" 1" 1-1/2" 1" 1-1/2"

3/4" 1" 1-1/2"

3/4" 1" 1-1/2" |

| PG 7/64" |  1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"

3" 4" 5" 6"

1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"

3" 4" 5" 6" 1" 1" |

| PG 1/8" |  1/8" 1/4" 5/16" 3/8" 1/2" 3/4" 1"

1-1/4" 1-1/2" 1-3/4" 2" 2-1/2" 3" 3-1/2"

4" 5" 6" 7" 8" 10" 12" 14"

1/8" 1/4" 5/16" 3/8" 1/2" 3/4" 1"

1-1/4" 1-1/2" 1-3/4" 2" 2-1/2" 3" 3-1/2"

4" 5" 6" 7" 8" 10" 12" 14" 1" 1-1/2" 1" 1-1/2"

1" 1-1/2" 2"

1" 1-1/2" 2" |

| PG 9/64" |  9/64" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

2-1/2" 3" 4"

9/64" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

2-1/2" 3" 4" |

| PG 5/32" |  5/32" 1/4" 5/16" 3/8" 1/2" 3/4" 1"

1-1/4" 1-1/2" 1-3/4" 2" 2-1/2" 3" 4"

5" 6" 7" 8"

5/32" 1/4" 5/16" 3/8" 1/2" 3/4" 1"

1-1/4" 1-1/2" 1-3/4" 2" 2-1/2" 3" 4"

5" 6" 7" 8" 1-1/2" 1-1/2" |

| PG 3/16" |  3/16" 1/4" 5/16" 3/8" 1/2" 3/4" 1"

1-1/4" 1-1/2" 1-3/4" 2" 2-1/2" 3" 4"

5" 6" 7" 8" 10" 12"

3/16" 1/4" 5/16" 3/8" 1/2" 3/4" 1"

1-1/4" 1-1/2" 1-3/4" 2" 2-1/2" 3" 4"

5" 6" 7" 8" 10" 12"  1" 1-1/2" 1" 1-1/2"

1" 1-1/2" 2"

1" 1-1/2" 2" |

| PG 7/32" |  5/16" 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2"

2" 2-1/2" 3" 4" 5" 6" 7" 8"

5/16" 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2"

2" 2-1/2" 3" 4" 5" 6" 7" 8" |

| PG 1/4" |  1/4" 5/16" 3/8" 1/2" 3/4" 1" 1-1/4"

1-1/2" 1-3/4" 2" 2-1/2" 3" 4" 5" 6"

7" 8" 10" 12" 14"

1/4" 5/16" 3/8" 1/2" 3/4" 1" 1-1/4"

1-1/2" 1-3/4" 2" 2-1/2" 3" 4" 5" 6"

7" 8" 10" 12" 14" 1" 1-1/2" 2" 1" 1-1/2" 2"

1-1/2" 2" 3"

1-1/2" 2" 3" |

| PG 9/32" |  9/32" 1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4"

2" 2-1/2" 3" 4" 5" 6"

9/32" 1/2" 3/4" 1" 1-1/4" 1-1/2" 1-3/4"

2" 2-1/2" 3" 4" 5" 6" |

| PG 5/16" |  5/16" 3/8" 1/2" 5/8" 3/4" 1"

5/16" 3/8" 1/2" 5/8" 3/4" 1" |

| Length |

18" amp;

18" amp;  36"

36" |

| HOT ROLLED |

1/8" x 1" - 1/8" x 1-1/2" - 5/32" x

1-1/2"

1/8" x 1" - 1/8" x 1-1/2" - 5/32" x

1-1/2" |

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply Jantz Supply

Jantz Supply  K & G Finishing Supplies

K & G Finishing Supplies Admiral STEEL

Admiral STEEL

AISI O-6 (GRAPH-MO TOOL STEEL)

AISI O-6 (GRAPH-MO TOOL STEEL)

Color Marking

Ends painted Aluminum, with Black stripe.

This is an oil hardening, non deforming tool and die steel with

remarkable machining properties. Because the graphite retains the lubricant,

it possesses excellent non-sizing properties. It also has good resistance to

wear and abrasion.

Typical Analysis

|

Carbon 1.45 | Manganese 1.00 |

Silicon 1.25 | Molybdenum 0.25 |

ATS-34 and ATS-55 STAINLESS STEEL

ATS-34 and ATS-55 STAINLESS STEEL

Manufacture/sales: ATS-34 was discontinued by Admiral Steel, and most of knifemaing supplies are out of this stock.

Not widely known Japanese alloy, ATS-55 is similar to ATS-34, but with the Molybdenum content reduced and new elements added.

It looks like the intent was to get ATS-34 edge-holding with increased toughness. Since Molybdenum

is an expensive element useful for high-speed steels, and knife blades do not need to be high speed,

using much less Moly hopefully decreases the price of the steel and at the same time retaining ATS-34 performance.

It is used by Spyderco.

ATS-34, a Hitachi product, is considered to be the ultimate, all around knife steel.

It is the Japanese version of 154 CM and, comparing the alloy content, these two steels are interchangeable.

154 CM was developed by Crucible Metals as a high temperature alloy for use in

fan-jet engines. 700 ℉would not soften it and has enough Chromium to

make it stainless in normal use.

Normally hardened to around 60 Rc, it holds an edge very well and is tough enough even at that high hardness. Not quite as rust resistant as the 400 series stainless.

Used by many custom makers, Spyderco (in their high-end knives) and Benchmade

Color coding

Color code on the end of the ATS-34 bars is Red.

Typical Analysis

| Carbon | Silicon | Manganese | Phosphorus | Sulfur | Chr | Moly | Copper | Cobalt | |

| ATS-34 | 1.03% | 0.25% | 0.41% | 0.026% | 0.001% | 13.74% | 3.56% | - | - |

| ATS-55 | 1.00% | 0.35% | 0.50% | 0.03% | 0.002% | 14.00% | 0.60% | 0.20 | 0.40 |

| 440-C | 1.04% | 0.74% | 0.36% | 0.003% | 0.003% | 16.92% | 0.46% | - | - |

| 154-CM | 1.05% | 0.30% | 0.50% | 0.030% | 0.030% | 14.00% | 4.00% | - | - |

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply K & G Finishing Supplies

K & G Finishing Supplies Jantz Supply

Jantz Supply

Texas Knifemaker's Supply

Texas Knifemaker's Supply Admiral STEEL

Admiral STEEL

AUS-4, AUS-6, AUS-8, AUS-10

AUS-4, AUS-6, AUS-8, AUS-10

Also designated 4A, 6A, 8A, 10A - are Japanese stainless steels, roughly

comparable to 440A (AUS-6, .65% carbon) and 440B (AUS-8, .75% carbon) and 440C

(AUS-10, 1.1% carbon).

AUS-6 is used by Al Mar.

Cold Steel's use of AUS-8 has

made it pretty popular, as heat treated by CS it won't hold an edge like ATS-34,

but is a bit softer and may be a bit tougher.

AUS-10 has roughly the same carbon content as 440C but with slightly less chromium, so it should be a bit less rust

resistant but perhaps a bit tougher than 440C. All 3 steels have some vanadium

added (which the 440 series lacks), which will improve wear resistance. No Tungsten.

Typical Analysis:

| Carbon | Chromium | Manganese | Molybdenum | Nickel | Silicon | Phosphorus | Sulfur | Vanadium | |

| AUS-4 | 0.4-0.45% | 13.00-14.50% | 1.00% | - | 0.49% | 0.04% | 1.00% | 0.03% | - |

| AUS-6 | 0.55-0.65% | 13.00-14.50% | 1.00% | - | 0.49% | 0.04% | 1.00% | 0.03% | 0.10-0.25% |

| AUS-8 | 0.70-0.75% | 13.00-14.50% | 0.50% | 0.10-0.30% | 0.49% | 0.04% | 1.00% | 0.03% | 0.10-0.26% |

| AUS-10 | 0.95-1.10% | 13.00-14.50% | 0.50% | 0.10-0.31% | 0.49% | 0.04% | 1.00% | 0.03% | 0.10-0.27% |

Sandvic 12C27 and 12C27 Modified

Sandvic 12C27 and 12C27 Modified

Scandinavian steel used often in Finish pukes and Norwegian knives.

Typical Analysis:

| Carbon | Chromium | Manganese | Phosphorus | Silicon | Sulfur | |

| Sandvic 12C27 | 0.025 | class="center">0.4 | 0.01 | 0.025 | 0.4 | 0.01 |

| Sandvic 12C27 MOD | 0.025 | 0.4 | 0.01 | 0.025 | 0.4 | 0.01 |

CPM 3V, CPM 10V, CPM 420V and CPM(T)440V

CPM 3V, CPM 10V, CPM 420V and CPM(T)440V

CPM S30V is the NEW addition from Crucible Materials Corp.

CPM S60V is a new designation for CPM 440V

CPM S90V is a new designation for CPM 420V.

CPM - Crucible Particle Metallurgy - steels are made by Crucible

Specialty Metals, and are super edge holding steels.

The process used to manufacture particle metallurgy permits unusually high Carbon and Vanadium content.

About Particle Metallurgy

The traditional process uses the pressing of blended metal powders into a

mold. The compacted part is then heated to just below the melting point. This

is called sintering.

Sintering is similar to forge welding, since the individual particles

are bonded without melting down. Parts can be produced that contain elements

impossible to include in casting procedures.

Like making porous filters for gas and oil lines, sintered bronze self

lubricated bearings, tungsten carbide cutting tool tips and replaceable

ceramic inserts.

Crucible Specialty Metals company advanced the process of particle metallurgy

in 1970 by introducing

Crucible Particle Metallurgy.

This process differs from traditional PM in that it is used to produce a large

compact (billet), which is than rolled or forged in conventional mills into

bars, rods, wire, sheet or plates required by the industry.

The wear resistance and strength of CPM steels are always greater than of the

steels made by conventional methods. The fine grain size and even distribution

of the alloy elements are the key.

Spyderco offers at least one model in CPM T440V

Comparison of CPM versus 440-C and 154CM Stainless:

| Carbon | Manganese | Silicon | Chromium | Molybdenum | Vanadium | |

| 440 C | 1.20 | 1.00 | 1.00 | 18.00 | 0.75 | 0.00 |

| 154 CM | 1.02 | 0.60 | 0.25 | 14.00 | 4.00 | 0.00 |

| CPM 3V | 0.80 | 0.50 | 0.90 | 5.23 | 1.30 | 9.75 |

| CPM 10V | 2.46 | - | - | 7.50 | 1.30 | 9.75 |

| CPM S60V (440V) | 2.30 | - | - | 14.00 | 1.00 | 9.00 |

| CPM S90V (420V) | 2.15 | 0.40 | 0.40 | 17.00 | 0.40 | 5.50 |

| CPM S30V | 1.45 | 0.40 | 0.40 | 14.00 | 2.00 | 4.00 |

| Hot Rolled |

class="green-ball" SRC="images/green.gif" Alt="Texas Knifemaker's Supply"> 1/8" thick x 1-1/2" wide x 1' + and 36"

long - Orange End

class="green-ball" SRC="images/green.gif" Alt="Texas Knifemaker's Supply"> 1/8" thick x 1-1/2" wide x 1' + and 36"

long - Orange End 3/16" thick x 1-1/2" wide x 1' + and 36" long - Orange End

3/16" thick x 1-1/2" wide x 1' + and 36" long - Orange End 1/8" thick x 1-1/2" wide x 18" and

36" long - White End

1/8" thick x 1-1/2" wide x 18" and

36" long - White End 5/32" thick x 1-1/2" wide x 18" and

36" long - White End

5/32" thick x 1-1/2" wide x 18" and

36" long - White End 3/16" thick x 1-1/2" wide x 18" and

36" long - White End

3/16" thick x 1-1/2" wide x 18" and

36" long - White End 3/16" thick x 2" wide x 18" and

36" long - White End

3/16" thick x 2" wide x 18" and

36" long - White End

|

| Precision ground |

3/32" thick x 1-1/2" wide x 18" and

36" long - White End

3/32" thick x 1-1/2" wide x 18" and

36" long - White End 1/8" thick x 1-1/2" wide x 18" and

36" long - White End

1/8" thick x 1-1/2" wide x 18" and

36" long - White End |

| Sheet |

3/32" thick x 6" wide x 12" long -

Orange End

3/32" thick x 6" wide x 12" long -

Orange End 3/32" thick x 6" wide x 24" long -

Orange End

3/32" thick x 6" wide x 24" long -

Orange End 3/32" thick x 6" wide x 36" long -

Orange End

3/32" thick x 6" wide x 36" long -

Orange End

|

CPM S30V

CPM S30V

It is a martensitic stainless steel designed to offer the best combination of toughness, wear resistance and corrosion resistance.

It's chemistry has been specially balanced to promote the formation of vanadium carbides which are harder and more effective than chromium carbides in providing wear resistance.

S30V offers substantial improvement in toughness over other high hardness steels such as 440C and D2,

and its corrosion resistance is equal to or better than 440C in various environments.

The CPM process produces very homogeneous, high quality steel characterized by superior dimensional stability, grindability, and toughness compared to steels produced by conventional processes.

Company no longer seem to exist, so the current Data Sheets are no longer available.

Company no longer seem to exist, so the current Data Sheets are no longer available.

Forging: 2100F (1150C) Do not forge below 1750F (950C).

Annealing: Heat to 1650F (900C), hold 2 hours, slow cool no

faster than 25F (15C) per hour to 1100F (595C), then furnace

cool or cool in still air to room temperature.

Annealed Hardness: About BHN 255

Stress Relieving

Annealed Parts: Heat to 1100-1300F (595-705C), hold 2

hours, then furnace cool or cool in still air.

Hardened Parts: Heat to 25-50F (15-30C) below

original tempering temperature, hold 2 hours, then

furnace cool or cool in still air.

Straightening: Best done warm 400-800F (200-430C)

Hardening Preheat: Heat to 1550-1600F (845-870C) Equalize.

Austenitize: 1900-2000F (1035-1095C), hold time at temperature 15-30 minutes.

Quench: Air or positive pressure quench (2 bar minimum) to below 125F (50C), or salt or interrupted oil quench to about 1000F (540C), then air cool to below 125F (50C).

Temper: Double temper at 400-750F (200-400C). Hold for

2 hours minimum each time.

A freezing treatment - may be used between the first and second tempers. Freezing

treatments help to attain maximum hardenability and must always be followed by at least one temper.

NOTE: For optimum stress relieving, CPM S30V may be tempered at 1000-1025F (540-550C). Tempering in this range

may result in a slight decrease in corrosion resistance. Size Change: +0.05 to +0.10% when fully martensitic. The

presence of retained austenite may reduce the net growth.

When tempering at 400-750F (200-400C), freezing treatments

may be necessary to minimize retained austenite.

Note: Properties shown throughout this data sheet are typical values.

Normal variations in chemistry, size and heat treat conditions may cause

deviations from these values. For additional data or metallurgical assistance,

please consult your local Crucible Service Center.

Recommended Heat Treatment:

Austenitize 1950F (1065C). Quench to below 125F (50C).

Double temper at 600F (315C) 2 hrs. minimum each temper.

Cool to hand warm between tempers. A freezing treatment may

be added between tempers.

Aim hardness: 58-61 HRC.

Listed in the catalog of:

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply

Texas Knifemaker's Supply

Texas Knifemaker's Supply

CRUCIBLE 154 CM STAINLESS STEEL

CRUCIBLE 154 CM STAINLESS STEEL

Crucible 154 CM is hardenable Chromium steel, to which Molybdenum has been

added to improve the hot-hardness characteristics. (It is also called 440 C

Modified). It was developed by Crucible Metals as a high temperature alloy for

use in fan-jet engines.

ATS-34 is a Japanese version of 154 CM and, comparing the alloy content, these

two steels are interchangeable.

Nominal Analysis

| Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Molybdenum. | |

| ATS-34 | 1.03% | 0.25% | 0.029% | 0.002% | 0.41% | 13.75% | 3.56% |

| 440-C | 1.20% | 1.00% | 0.040% | 0.030% | 1.00% | 18.00% | 0.75% |

| 154-CM | 1.05% | 0.60% | 0.030% | 0.030% | 0.25% | 14.00% | 4.00% |

| As hardened | 700 F | 900 F | 1000 F | 1050 F | 1100 F | 1200 F | |

| 1850 F | 59 Rc | 56 | 58 | 56 | 52 | 46 | 40 |

| 1900 F | 60 Rc | 56 | 57 | 58 | 52 | 48 | 44 |

| 1950 F | 61 Rc | 57 | 60 | 56 | 56 | 48 | 46 |

| 2000 F | 61Rc | 57 | 61 | 62 | 58 | 51 | 47 |

| 2050 F | 59 Rc | 54 | 57 | 55 | 61 | 53 | 48 |

| 2100 F | 52 Rc | 50 | 52 | 55 | 62 | 55 | 60 |

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply K & G Finishing Supplies

K & G Finishing Supplies Jantz Supply

Jantz Supply

Texas Knifemaker's Supply

Texas Knifemaker's Supply

CRUMVEAR

CRUMVEAR

No data

| Color code- RED/BLUE |  1/8" x

1-1/2" - priced per foot 1/8" x

1-1/2" - priced per foot

|

Texas Knifemaker's Supply

Texas Knifemaker's Supply

L-6

L-6

This is a band saw steel that is very tough and holds an edge well, but rusts

easily. It is, like O-1, easy to work with. Rusts readily without proper maintenance.

Some say that this may be one of the very best steels available for cutlery, especially where toughness is desired,

but my personal choice for that purpose is stainless.

Typical Analysis:

| Carbon | Chromium | Manganese | Molybdenum | Nickel | Silicon | Tungsten | Vanadium |

| 0.65-0.75% | 0.60-1.20% | 0.25-0.80% | 0.50% | 1.25-2.00% | 0.50% | - | 0.20-0.30% |

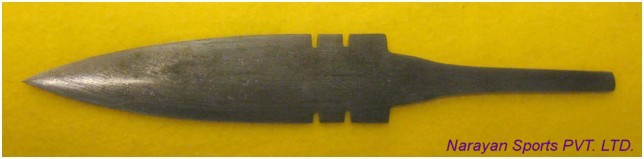

WOOTZ - Origins of Damascus steel

WOOTZ - Origins of Damascus steel

as the age of iron followed the bronze age, a major discovery of the first steel alloy was made in India.

How early it was discovered is still a mystery, possibly even ear;ier than 300 BC.

This alloy called Wootz was traded in the city of Damascus in Syria - the major trading center of the Orient.

It is said that the Wootz, traded in one pound ingots and was so precious it traded for equal weight in gold.

It was so precious that thin layer of Wootz was fused to a layer of plain iron bar, then to make it strong and unbreacable, it was folded to form many layers.

It became known as Damascus steel because the majority of supper quality swords were made and traded in Damascus.

They were superior to European swords in strength, edge sharpness, and cutting ability.

It is said that Damascus sword could cut a silk handkerchief thrown in the air

in half, impossible feat with European blade, and still super hard to acheave today with most modern technology and craftsmanship.

Wootz small ingots - about 1 lb. each, were made by melting iron ore with charcoal in sealed clay crucibles, or crucibles with tight fitting lids.

The locak iron ore also contained other elements to further improve this steel alloy.

More reading: Wikipedia reference

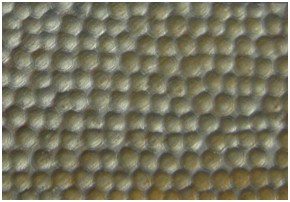

Definition of Damascus steel

It is a steel with a pattern on the surface. It is also any steel that has

either crystalline or mechanical structure brought out and highlighted by acid

etching. Patterned steel or layered steel.

Damascus Steel Types:

Damascus Steel Types:

| Carbon | Manganese | Chromium | Phosphorus | Sulfur | Co per | Nickel | Silicon |

| 1.4-1.7% | 0.06% | trace | 0.1% | 0.02% | 0.04% | 0.03% | 0.04% |

Unfinished blanks of various sizes and patterns are available from many

Knifemaker's supplies.

Unfinished blanks of various sizes and patterns are available from many

Knifemaker's supplies.

440-C and D2 Damascus

440-C and D2 Damascus

This Damascus steel is formed into billets and is available by the inch in the

sizes listed in the table below. It is fully guaranteed against defects.

Instructions for tempering and etching are available.

|

Raindrop Ladder Random |

1/8" x 1-1/8" Billets (4" through 16")

1/8" x 1-1/8" Billets (4" through 16") 1/8" x 1-1/8" Billets TWISTED (4" thrum 16")

1/8" x 1-1/8" Billets TWISTED (4" thrum 16") 1/8" x 1-1/2" Billets (4" thrum 16")

1/8" x 1-1/2" Billets (4" thrum 16") 3/16" x 1-1/2" Billets (4" thrum 16")

3/16" x 1-1/2" Billets (4" thrum 16") 3/16" x 1-1/2" Billets TWISTED (4" thrum 16")

3/16" x 1-1/2" Billets TWISTED (4" thrum 16") 1/48" x 2" Billets (4" thrum 16")

1/48" x 2" Billets (4" thrum 16") 1/4" x 2" Billets TWISTED (4" thrum 16")

1/4" x 2" Billets TWISTED (4" thrum 16") |

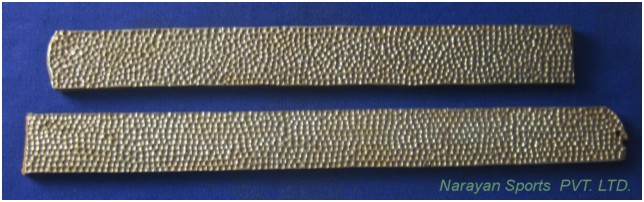

Tim Zowada's O1 and L6 steel billets

Tim Zowada's O1 and L6 steel billets

| Random pattern |

1/8" x 1-1/8" x 7-1/5" or 15" -

Hot forged

1/8" x 1-1/8" x 7-1/5" or 15" -

Hot forged 3/16" x 1-1/2" x 7-1/5" or 15" -

Hot forged

3/16" x 1-1/2" x 7-1/5" or 15" -

Hot forged 1/4" x 1-1/2" x 7-1/5" or 15" -

Hot forged

1/4" x 1-1/2" x 7-1/5" or 15" -

Hot forged 1/4" x 2" x 7-1/5" or 15" - Hot

forged

1/4" x 2" x 7-1/5" or 15" - Hot

forged

|

5160 and 1018 Damascus steel billets (512 layers)

5160 and 1018 Damascus steel billets (512 layers)

|

Random pattern 8" and 16" |

3/32", 1/8", 5/32" and 3/16" x

1"

3/32", 1/8", 5/32" and 3/16" x

1" 3/32", 1/8", 5/32" and 3/16" x

1-1/2"

3/32", 1/8", 5/32" and 3/16" x

1-1/2" 3/32", 1/8", 5/32" and 3/16" x

2"

3/32", 1/8", 5/32" and 3/16" x

2" 1/8", 5/32" and 3/16" x 4"

1/8", 5/32" and 3/16" x 4"

|

Mike Norris's 'Stainless Steel Plus' - D2 / 302 SS /

AEBL.

Mike Norris's 'Stainless Steel Plus' - D2 / 302 SS /

AEBL.

| Random pattern |

1/8" x 1" and 1-1/2" x 8",

5/32" x 1-1/2" x 8", 1/8", 3/16" and 1-1/2" x

8" and 12", 1/4" x 1-1/2" x 12"

1/8" x 1" and 1-1/2" x 8",

5/32" x 1-1/2" x 8", 1/8", 3/16" and 1-1/2" x

8" and 12", 1/4" x 1-1/2" x 12"

|

| Banded Ladder |

1/8" x 1" and 1-1/2" x 8",

5/32" x 1-1/2" x 8", 1/8", 3/16" and 1-1/2" x

8" and 12", 1/4" x 1-1/2" x 12"

1/8" x 1" and 1-1/2" x 8",

5/32" x 1-1/2" x 8", 1/8", 3/16" and 1-1/2" x

8" and 12", 1/4" x 1-1/2" x 12"

|

| Banded Twist |

1/8" x 1" and 1-1/2" x 8",

5/32" x 1-1/2" x 8", 1/8", 3/16" and 1-1/2" x

8" and 12", 1/4" x 1-1/2" x 12"

1/8" x 1" and 1-1/2" x 8",

5/32" x 1-1/2" x 8", 1/8", 3/16" and 1-1/2" x

8" and 12", 1/4" x 1-1/2" x 12"

|

1095 and 203E (160 layers)

1095 and 203E (160 layers)

| Random pattern |

1/8" x 1" x 4", 1/8" x 1-1/2" x 5" and 8",

3/16" x 1-1/2" x 5" and 8", 1/4" x 1-1/2" x 10"

1/8" x 1" x 4", 1/8" x 1-1/2" x 5" and 8",

3/16" x 1-1/2" x 5" and 8", 1/4" x 1-1/2" x 10" |

Double Stainless by Devin Thomas

Double Stainless by Devin Thomas

| Ladder & Raindrop |

1/8" x 1", 1/8", 5/32", 3/16", 1/4" x

1-1/4"

1/8" x 1", 1/8", 5/32", 3/16", 1/4" x

1-1/4"

1/8", 5/32", 3/16", 1/4" x

1-1/2",

1/4" x 2"

1/8", 5/32", 3/16", 1/4" x

1-1/2",

1/4" x 2" |

|

1095 and Nickel (High contrast

Carbon)

1095 and Nickel (High contrast

Carbon)

|

Serpentine Ladder Raindrop & Twist |

1/8", 5/32", 3/16", 1/4" x 1-1/4"

1/8", 5/32", 3/16", 1/4" x 1-1/4"

1/8", 5/32", 3/16", 1/4" x

1-1/2",

1/4" x 2"

1/8", 5/32", 3/16", 1/4" x

1-1/2",

1/4" x 2" |

|

1084 and 15 N 20 (High Carbon)

1084 and 15 N 20 (High Carbon)

|

Turkish Twist Firestorm |

1/8" x 1" or 1-1/4" or 1-1/2"

1/8" x 1" or 1-1/4" or 1-1/2"

5/32" x 1" or 1-1/4" or

1-1/2"

5/32" x 1" or 1-1/4" or

1-1/2"

3/16" x 1" or 1-1/4" or

1-1/2"

3/16" x 1" or 1-1/4" or

1-1/2"

|

|

|

1095 & 01 - Thunderforged® Damascus

1095 & 01 - Thunderforged® Damascus

This product is no longer available

| Twist Pattern #1 & #2 contains 88 layers Birdseye Pattern contains 240 layers |

|

Heating the Blade

The blade should be evenly heated to a bright red/dull orange color. This should

be achieved between 1,400 & 1,500 ℉(760 & 815 degrees C). Be careful

not to overheat. Quenching an overheated blade will increase the change of

cracking or warping.

Another good method it to heat the blade until the magnetic properties are lost.

To test that a blade is ready to quench a magnet may be used. Once there is

little or no attraction between the blade and magnet the blade will have reached

the proper temperature and is ready to quench.

Quenching the Blade

Quenching is performed in either light oil (we recommend olive old with clove -

quenches well we find), or a standard quenching oil. Or use a brine solution

(salt & water). Dissolving salt in boiling water until it no longer dissolves

makes a brine solution. The brine quench will make the blade much harder as it

will cool the steel much faster than the oil. The oil quench is well suited to a

large blade where toughness is more needed whereas the brine quench is more

suited to the small skinner and folder blades where holding an edge is

important. The blade should be quenched either point first or spine first in

order to minimize the chance of cracking or warping. Care must be taken when

quenching in brine. The quicker the blade is cooled the more likely it is to

crack. A good precaution is to preheat the brine to around 100 ℉(38 C)

prior to quenching. The oil quench is well suited to a large blade where

toughness is more needed whereas the brine quench is more suited to the small

skinner and folder blades where holding an edge is important.

Drawing the Temper of the Blade

Drawing, or tempering the blade is done by heating the steel in an oven. The

blade is placed in a heat treat oven and brought to a specific temperature. It

is then allowed to soak at that temperature to assure a full even heat. The

specific temperature determines the relative hardness of the blade.

It should be noted that some parts of all nickel Damascus may test somewhat

softer due to the nickel content.

Following table is approximate, because the 1095 and O1 have slightly different

hardness at the same tempering temperatures.

Note

When heat treating multiple blades keep ample space

between each blade for proper air circulation.

Hardness table for Thunderforged® Damascus

| °F/C | As quenched | 350/176 | 400/204 | 450/232 | 500/ 260 | 550/287 | 600/315 |

| Hardness(Rc) | 64-65 | 63-65 | 61-64 | 60-63 | 58-61 | 56-59 | 57-59 |

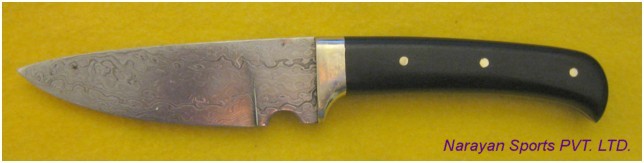

Damascus from India as it is made today

Damascus from India as it is made today

| Carbon | Manganese | Chromium | Molybdenum | Vanadium |

| x | x | x | x | x |

Gingami-1 / GIN-1 / G-2

Gingami-1 / GIN-1 / G-2

Gingami-1 aka GIN-1 aka G-2. A steel with slightly less Carbon, slightly more Chromium, and

much less than ATS-34. No Nickel, Tungsten or Vanadium. A very good stainless

steel.

Molybdenum

It is used often by Spyderco

| Carbon | Chromium | Manganese | Molybdenum | Phosphorus | Silicon | Sulfur | |

| GIN-1 | 0.90% | 15.50% | 0.60% | 0.30% | 0.02% | 0.37% | 0.03% |

420 Hardenable Stainless Steels

420 Hardenable Stainless Steels

420 steel grade finds application in cutlery such as carving knives, table knives and so on.

Grade 420 steels have good corrosion resistance against food, but continuous exposure of metals to unwashed food substances can lead to pitting corrosion.

Grade 420 stainless steel is a high-carbon steel with a minimum chromium content of 12%.

Like any other stainless steel, grade 420 can also be hardened through heat treatment up to 50HRC.

This is less hardness then anealed 440-C at 53HRC - A decent sharp cutting edge holding starts at 57HRC.

420 offers good ductility in its annealed state and some corrosion resistance properties when the metal is polished and hardened.

The first 12% of chromium in the alloy is changed to chromium carbides by heat treatment.

That leaves very little free chromium for good rust resistance.

Typical Analysis

| Carbon | Chromium | Manganese | Silicone | Phosphorus | Sulfur | |

| 420 | <0.15% | 12.0-14.0% | <1.0% | <1.0% | <0.04% | >0.03% |

440-A, 440-B, UNILOY 440C, 440F, 440F-Se, and 440-XH Hardenable Stainless Steels

440-A, 440-B, UNILOY 440C, 440F, 440F-Se, and 440-XH Hardenable Stainless Steels

The 440-A and 440-B Stainless Steels are low on Carbon and used for mass produced knives with softer blades.

I suspect every knife stamped as just 440, or 400 Series Stainless was made out of these cheaper steels. Lots come from abroad and it is not readily available from knifemaking supply outlets.

The SOG Seal 2000 is 440A, and Randall uses 440B for their stainless knives.

400-F & XH series are not use in knifemaking

440C stainless steel is considered a high-quality stainless steel, and has the highest level of carbon available for knife making.

Typical Analysis

| Carbon | Manganese | Phosphorus | Sulfur | Molybdenum | Chromium | Selenium | Silicone | Vanadium | Nickel | |

| 440-A | 0.45-0.75 | 1.00 max | 0.04 max | 0.03 max | 0.75 max | 16-18.00 | 0.75 max | 1.00 | - | - |

| 440-B | 0.75-0.95 | 1.00 max | 0.04 max | 0.03 max | 0.75 max | 16-18.00 | 0.75 max | 1.00 | - | - |

| 440-C | 0.95-1.20 | 1.00 max | 0.040 max | 0.030 max | 1.00 max | 18.00 | 0.75 max | 0.00 | - | - |

| 440-F | 0.95-1.20 | 1.00 max | 0.040 max | 0.05 min | 1.00 max | 18.00 | - | 0.40 | - | - |

| 440-F-SE | 0.95-1.20 | 1.00 max | 0.040 max | 0.030 max | 1.00 max | 18.00 | 0.75 max | 0.10 min | - | - |

| 440-XH | 1.60 | 0.50 | - | - | 0.80 | 16.00 | 0.75 max | 0.40 | 0.45 | 0.35 |

| °F | Quenched | 300 | 400 | 500 | 98% | 700 | 800 | 900 | 1000 | 1100 |

| Hardness(Rc) | 60.0 | 59.0 | 57.5 | 56.0 | 55.0 | 55.0 | 56.0 | 57.0 | 52.5 | 43.0 |

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply K & G Finishing Supplies

K & G Finishing Supplies Jantz Supply

Jantz Supply

Texas Knifemaker's Supply

Texas Knifemaker's Supply Admiral STEEL

Admiral STEEL

W-1 Spring Steel

W-1 Spring Steel

Most files are made from W-1, which is the same as W-2 except for less Vanadium and more Tungsten

| Flat bar |

1/16" x 1/8"

x 12" - priced per foot

1/16" x 1/8"

x 12" - priced per foot

|

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply

W-2 Tool Steel

W-2 Tool Steel

| Color CodeBLACK |  1/4" x

1-1/4" - priced per foot 1/4" x

1-1/4" - priced per foot

|

Texas Knifemaker's Supply

Texas Knifemaker's Supply

| Carbon | Chromium | Manganese | Molybdenum | Nickel | Silicon | Tungsten | Vanadium | |

| W1 | 0.70-1.50% | 0.15% | 0.10-0.40% | 0.10% | 0.20% | 0.10-0.40% | 0.50% | 0.10% |

| W-2 | 0.85-1.50% | 0.15% | 0.10-0.40% | 0.10% | 0.20% | 0.10-0.40% | 0.15% | 0.15-0.35% |

440-C Cast Dendritic Stainless Steel

440-C Cast Dendritic Stainless Steel

No data

| Sizes |  1/8", 3/16" and 1/4"

x 1-1/4" x 10"

1/8", 3/16" and 1/4"

x 1-1/4" x 10"

|

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply

1095 Hi Carbon Steel

1095 Hi Carbon Steel

Make springs, blades, small parts. you will find many uses around the shop

for this excellent quality high carbon steel. Bright finish, annealed.

The 10-series -- 1095 (and 1084, 1070, 1060, 1050, etc.) Many of the 10-series steels for cutlery, though 1095 is the most popular for knives. When you go in order from 1095-1050, you generally go from more carbon to less, from better edge holding to less edge holding, and tough to tougher to toughest.

As such, you'll see 1060 and 1050, used often for swords. For knives, 1095 is sort of the "standard" carbon steel, not too expensive and performs well.

It is reasonably tough and holds an edge very well. It rusts easily. This is a simple steel, which contains only two alloying elements: 0.95% Carbon and 0.4% Manganese.

The various Kay-Bar blades are usually 1095 with a black coating.

Hardening

Bring to 1425- 1450 °Fahrenheit, than quench immediately, holding at a

non-crucial

point such as the back of the blade or handle area.

Tempering

Temper between 400 - 600 °Fahrenheit, depending upon the desired

hardness.

| Flat bar |

1/8" x 1-1/2" x 9" and 12" and

18" 1/8" x 1-1/2" x 9" and 12" and

18" 3/16" x 1-1/2" and 2" x 9" and 12"

and 18" 3/16" x 1-1/2" and 2" x 9" and 12"

and 18" 1/4" x 2" x 18" - 1075 1/4" x 2" x 18" - 1075

|

Jantz Supply

Jantz Supply  Admiral STEEL

Admiral STEEL

52100 BALL BEARING STEEL

52100 BALL BEARING STEEL

Besides using ball and roller bearings, races/balls/rollers, it can be

obtained in bar stock.

In comparison to 5180, 50100B and O-1, it has more Carbon and more

Chromium.

Carbon heightens the abrasion resistance and Chromium hardeners deeper with

simpler heat treatments and makes the blade stronger. It does not take much

Chromium, even 0.5% is enough.

Typical Analysis:

| Carbon | Manganese | Chromium | Vanadium | Tungsten | Silicon | |

| 52100 | 1.10% | 0.35% | 1.50% | - | - | 0.35% |

| 5180 | 0.60% | 0.80% | 0.80% | - | - | - |

| 50100B | 0.95% | 0.45% | 0.45% | 0.20% | - | - |

| O-1 | 0.90% | 1.60% | 0.50% | - | 0.50% | - |

Sheffield's Knifemaker's Supply

Sheffield's Knifemaker's Supply

Lescalloy® BG42® VIM-VAR

Lescalloy® BG42® VIM-VAR

Applications

A high performance CR-MO-V alloy for aircraft gears, ball screws,

bearings and other critical applications

BG-42 is somewhat similar to ATS-34, with two major differences: It has more Carbon, Chromium and Manganese than ATS-34, and has 1.2% Vanadium (ATS-34 has no Vanadium), so look for even better

edge-holding than ATS-34.

Used by Bob Loveless, Chris Reeves in his Sebenzas.

Typical Analysis:

| Carbon | Chromium | Manganese | Molybdenum | Silicon | Vanadium | |

| BG-42 | 1.15% | 14.50% | 0.50% | 4.00% | 0.30% | 1.20% |

| Carbon | Chromium | Manganese | Molybd. | Silicon | Phosphorus | Sulfur | |

| ATS-34 | 1.04% | 13.93% | 0.40% | 3.55% | 0.28% | 0.029% | 0.002% |

| 440-C | 1.20% | 18.00% | 1.00% | 0.75% | 1.00% | 0.040% | 0.030% |

| 154-CM | 1.02% | 14.00% | 0.60% | 4.00% | 0.25% | 0.030% | 0.030% |

|

Flat bar Sold in 12" increments |

1-1/4" x .160"

1-1/4" x .160"  1-1/2" x .130" .160" and .187"

1-1/2" x .130" .160" and .187"  2" x .250"

2" x .250" |

Weight .68 Lbs/Ft Weight .66, .82, .95 Lbs/Ft Weight 1.70 Lbs/Ft |

Admiral STEEL

Admiral STEEL

N690 Stainless Steel

N690 Stainless Steel

N690 is manufactured by Bohler Uddeholm (German company) and is their trade name for 440C.

It is a common steel used for knife making in South Africa

Have not found the supplier yet, only snippets of unofficial information.

This steel also called Austrian Cobalt steel - alloy containing 17% Chromium, Molybdenum, Vanadium, and Cobalt.

Hi percentage of free Chromium makes it very stain resistant - if true at 17%, it would actually have the second highest Cr content - 440-C has the most at 18%.

Hardness 60 HRC

Extrema Ratio knives are made in a Extrema Ratio custom shop in Italy and is not nearly as well know in the United States as other companies. Started in 1997, they have taken the tactical world by storm. Many of the soldiers and armed men and women of the world carry Extrema Ratio.

The result is a blade with a very hard edge (hardened and tempered to 60 HRC) that is very sharp, very long lasting with an elastic and tough body.

The Red line of Bench Mark will be made in Taiwan - uses N690 Cobalt SS

There's at least three types of N690 steel -?

Leatherman Squirt P4

Typical Analysis:

| Carbon | Chromium | Cobalt | Molybdenum | Vanadium | |

| N690 | 1.07% | 17% | 1.5% | 1.1% | 1.1% |

5160H CARBON CHROMIUM SPRING STEEL

5160H CARBON CHROMIUM SPRING STEEL

Applications

This is carbon chromium grade of spring steel. As the name implies, this grade

is primarily used in the manufacture of automotive leaf springs. Other uses

include scrapers, equalizers, bumpers etc.

It has a high yield-tensile strength ratio, excellent toughness and high

ductility.

5160 is a steel popular with forgers, and is a very high-end steel. It has good edge holding, but is known

especially for its outstanding toughness (like L-6). Often used for swords (hardened in the low 50 Rc) because of its toughness, and is also used for hard use knives (hardened up near the 60 Rc).

Typical Analysis:

| Carbon | Chromium | Manganese | Phosphorus | Silicon | Sulfur | |

| 5160H | .55/.65% | .60/1.00% | .65/1.10% | .035 Max% | .15/.35% | .04 Max% |

| Forging | Normalizing | Annealing | Hardening |

| Heat to 2100-2200 F | Heat to 1600-1700 F Cool in air |

Heat to 1450-1550 F Cool in furnace | Harden in oil Quench at 1525 F Temper 800-1300 F |

| Sizes HR 5160 |

13/64" x 1.5"- 1.75"- 2"

13/64" x 1.5"- 1.75"- 2" 1/4" x 1"- 1.25"- 1.5"- 1.75"- 2"-

2.5"- 3" - 4"

1/4" x 1"- 1.25"- 1.5"- 1.75"- 2"-

2.5"- 3" - 4" |

Admiral STEEL

Admiral STEEL

HEAT TREATING INFORMATION FOR SPRING STEEL

HEAT TREATING INFORMATION FOR SPRING STEEL

This specification covers Annealed High Carbon Spring Steel for working

springs which must be formed before the heat treatment. In the annealed

condition this material is capable of being bent flat on itself either with or

across the grain, in thicknesses under .050".

Suggested Heat Treatment:

Heat according to chart. Quench in oil. For C 1095, quench in water. The

spring should than be drawn to the hardness best suited for its purpose.

The following properties may be expected:

| Formed Springs Requiring Heat Treatment | AISI C 1050 | AISI C 1065 | AISI C 1075 | AISI C 1095 | ||||

| Normalizing Annealing Hardening As Quenched Hardness |

1550 - 1650 F 1400 - 1500 F 1475 - 1550 F Rc 58 |

1550 - 1650 F 1400 - 1500 F 1475 - 1550 F Rc 62 |

1550 - 1650 F 1400 - 1500 F 1475 - 1550 F Rc 64 |

1550 - 1650 F 1400 - 1500 F 1475 - 1550 F Rc 66 |

||||

| Drawing Temp. 400 F 600 F 700 F 800 F 900 F 1000 F 1100 F 1200 F |

Rockwell Rc 52 Rc 45 Rc 39 Rc 35 Rc 31 Rc 27 Rc 22 --- |

Tensile PSI 250,000 210,000 180,000 160,000 139,000 124,000 112,000 --- |

Rockwell Rc 57 Rc 50 Rc 46 Rc 42 Rc 39 Rc 35 Rc 28 Rc 22 |

Tensile PSI 295,000 240,000 215,000 190,000 180,000 160,000 125,000 1 20,000 |

Rockwell Rc 59 Rc 53 Rc 47 Rc 44 Rc 40 Rc 36 Rc 32 Rc 26 |

Tensile PSI 305,000 255,000 230,000 205,000 182,000 162,000 140,000 1 22,000 |

Rockwell Rc 62 Rc 55 Rc 49 Rc 45 Rc 41 Rc 38 Rc 34 Rc 30 |

Tensile PSI 320,000 270,000 238,000 212,000 189,000 176,000 155,000 1 38,000 |

Admiral STEEL

Admiral STEEL

Some Steel Terms, Traits & Elements

Some Steel Terms, Traits & Elements

Stainless Steel Alloys:

Stainless Steel Alloys:

is an alloy of iron that must contain Carbon. it is the most important hardening element. Other elements may be added for specific applications.

The most important element which increases the strength of the steel, and without the high enough percentage, alloy would not harden.

contains minimum of .5% carbon, higher the %, higher hardness can be achieved

Designation First numbers - 10 means plain carbon steel, any other number designate alloy steel.

50xx serie is a chromium steel.

SAE designation system, steels with letter designations are tool steels - W-1, O-1, D-2

Designation Last numbers of a steel specify the steel's carbon content = 1095 has 0.95% carbon. 52100 has 1.0% carbon. 5160 has 0.60% carbon.

- Gives the alloy it corrosion resistance, forms chromium carbides for wear resistance, and hardenability.

It should be noted that at the higher end of the Chromium

scale a steel becomes more brittle esp., at the higher level of hardness.

- is a steel with at least 13% chromium. The first 11% dissolves and form carbides, left over are your rust resistance.

Higher the %, more free chromium, more rust resistance.

All stainless steel alloys can rust, they are only rust resistant, not rust proof. As with plain high carbon steels, proper blade maintenance is needed, though not as much.

- Manganese helps the grain structure, and contributes to hardenability.

Also strength & wear resistance. Improves the steel (e.g., deoxidize's) during the steel's manufacturing (hot working and rolling). Present in most cutlery steels except for A-2, L-6, and CPM 420V.

- Forms carbides, prevents brittleness & maintains the steel's strength at high temperatures. It is added to many steel alloys, to enable them to harden in the air.

Increases strength, hardness, hardenability and toughness. Improves machinability and resistance to corrosion

A-2, ATS-34) always have 1% or more Molybdenum

- Enhancer for strength, corrosion resistance, and toughness.

Present in L-6 and AUS-6 and AUS-8.

- Increases strength, and wear resistance.

Like manganese, it makes the steel more sound while it's being manufactured.

- Increases wear resistance. When combined properly with chromium or Molybdenum, tungsten will make the steel to be a high-speed steel. The high-speed steel M-2 has a high amount of tungsten.

Popular name for Tungsten steels are Hi speed steels

- Forms finely structured carbides to enhance wear resistance, toughness, and hardenability.

A number of steels have vanadium, but M-2, Vascowear, and CPM T440V and 420V (in order of increasing amounts) have high amounts of vanadium. BG-42's biggest difference with ATS-34 is the addition of vanadium. Also D2, S30V.

- Increases strength and hardness and permits

quenching in higher temperatures. Intensifies the individual effects of other

elements in more complex steels.

- The final hardness of steel is determined using a

Rockwell Test and the result is displayed in HRC - for the example level of your average butchers knife is 55 HRC.

When a knife is labeled as 58-60HRC, it is best to take the mean of 59HRC e.g. as it is rare to find the majority of

blades being 58 or 60. The figures listed above refer to the optimum or the

maximum of hardness for a particular steel. 440C for example is listed at 60HRC

any harder then this steel is subject to brittleness due to its high level of

Chromium.