Tip on do it yourself horn / bone stabilizing

Yes bones can shrink over the years.

Here is a tip.

Soak the bones BEFORE you start to work it in some oil, baby oil etc. for

about 2 weeks.

You may want to try linseed oil, I have heard better success from that

oil.

Let it naturally dry out for 3 months or so, and it removes about 99.9%

chance of cracking and shifting.

I know it is a long process, but that is all I know of.

Plus that means you have to keep ready inventory of everything in

advance.

Also, to color all types of bone, leather etc, use potassium permanganate -

we sell it $18.00/lbs.

If you come up with a better method let me know.

Ric Chopra - Universal Agencies

Inc. - Knife Supplies inc.

Noticing that all natural horn and antler, if left untreated, shrinks a lot in a short time (a couple of month).

Most noticeable on a stacked handles where any metal spacers are used, or as scales on a full tangs.

Have been avoiding using these materials for that reason in the past.

Looking for a reasonably fast solution, I tried placing the untreated antler, and soft wood scales or semi-finished handles in Wood Hardener with good results.

Wood Hardener is a milky penetrant used for treating wood rot and is readily available through Hardware Sales stores.

I have made a 3" PVC cylinder to hold a 16" bowie knife to cover all sizes of knives I make, with a PVC plug glued to bottom of tube.

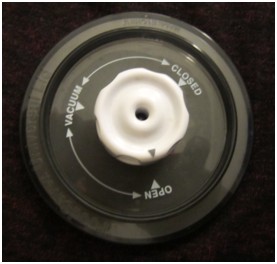

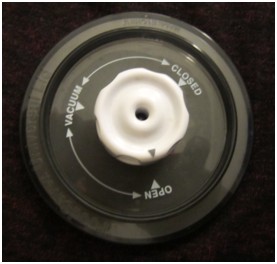

The lid is a universal Foodsaver lid for vacuum sealing Mason jars. It does have a wide flat rubber seal on the bottom for different diameter jars, and a vacuum locking valve built in.

Place a bunch of handle material, or finished knife, handle down into cylinder directly, or lower in a wire basket, pour in the Wood Hardener to cover the handle completely, then suck out the air, vacuum sealing the container. Left over night, Wood hardener will penetrate the materials as far as it will be able to. Finish the handle or scales as close to done as possible before this treatment so this protective layer will not be sanded off with the final finishing.

The Wood Hardener can be reused, so pour back into bottle for storage.

Let dry-cure for few days before final finish.

Polishes handsomely and it is sealed. No measurable shrinkage during six month.

Tony - *AJH* Custom Knives & Services

|

|

Tip on do it yourself horn / bone coloring

If you can't find any potassium permanganate (in any form), however you can

use Aniline Stain, powder form/mix with wood alcohol. Really came out nice, the

bone took the color really good, different shades in different areas. I got the

info from a book by Ben Kelley, THE COMPLETE BOOK of POCKETKNIFE REPAIR...page.

80, potassium permanganate tablets. No one but him evidently knows where to get

them.

Tela & Larry Patterson

Another tip for fast bone coloring

Tip for coloring bone or antler. Tried the hot shoe polish tip from a mag and liked the color

but it was so shallow the first time some one scratched the handle you would see white underneath so I

tried some leather dye and it works wonders. So if I have a antler that has no

color I take out my leather dyes and get to work. The best thing is you can do

multiple colors for an aged effect and if its scratched you see more color sweet.

Brandon Sawisch

Tip on storing your blade

No matter how good you take care of your knife, while hunting or enjoying

other outdoor activities, it is time to reinforce the fact that even the

best Stainless Steels are only rust resistant and not rustproof.

All blades will rust in a very short time if left in the moist sheath, or

wrapped in the oily rag under the seat of your 4x4.

If you live close to the ocean, you know how fast can any metal rust, due to

the salt always present in the air. and eventually permeating your knife

sheath.

Oiling your knife will slow this down a little bit, but not

significantly.

The trick is to dry your knife and sheath thoroughly - I leave mine on the

baseboard heater set for medium heat over night. This have cured even a

knife found in the grass after a month of rain, leather sheath was

resembling soggy moccasin and the handle was swollen out of proportion.

Good thing is to store your knife out of it's sheath, in the dry place. Some

leathers are tanned with tannin

acids which cannot be totally neutralized. Moisture in the sheath will leach

the acid onto your blade and rust follows.... Also do wipe any finger prints

of the blade - the sweat also contain acids.

There are few products which claim to make your blade rustproof : -

Renaissance Wax - White Lightning - Tuf-Cloth and Rust Free but nobody is

making the leather sheath water proof.

Tip for leather. I use clear

paraffin wax (used for sealing preserves). Heat your sheath and brush melted

paraffin onto it till it is fully saturated and will not absorb any more. I

submerge the sheath in the can of melted paraffin and do even the insides,

leave it in for about 5 minutes than drain and wipe all surface excess while

hot.

It is water proof and totally non-toxic, so no to worry if you do not get it

off the blade before use.

Tony - *AJH* Custom Knives & Services

Etching Instructions for Thunderforged™ Damascus

- Clean the blade with Acetone

- Soak in etching solution

- Rinse in water & soap

- Oil

Detailed Instructions

After cleaning / degreasing the blade with the Acetone, make sure that you do

not touch it with bare hands, since the oils from your fingers will harm the

results. Recommended to use tweezers and or rubber / surgical gloves.

Dip the blade, tip down, into your plastic or glass container with the pre mixed

etching solution.

Leave the blade in for 15 to 20 minutes. Pull the blade out and inspect how the

etch looks like. If you need a higher contrast dip the blade into the solution

for additional time, till you reached the desired contrast.

Do regularly check your blade while in the solution.

Once satisfied with the contrast, you pull the blade out of the solution and

immediately rinse it in lukewarm water and rub hand soap on it simultaneously.

At this time you will notice that a black substance will be washing off - this

is the carbon removed during the etch.

Keep washing the blade till no more black carbon is coming off.

The next step is to oil the blade with a good quality gun oil.

Even after you have oiled it, you can go back to step one, to start all over to

reach even higher contrast if desired.

Etching solution ingredients

50% PCB Etchant Solution (available at Radio Shack® )

50% White Vinegar.

Mix together in plastic or glass container, DO NOT USE ANY METAL

container.

Etching and Heat treating instructions are included with every purchase.

(Thunderforged® is a registered trademark of Universal Agencies, Inc.)

www.knifesupplies.com

Repairing Ivory

AcryliKey is a registered ivory repair system which has been designed by the

manufacturer, specifically, for the repair of ivory piano keys.

However, in case where the scale replacement is not an option, this system could

be possibly and successfully used for any knife scale repairs.

Full page of Ivory repair instructions and tips are located on the company's web page at:

Preserving leather

For the preserving of leather I just use a product called "FLUID FILM".

It is a lanolin based lubricant, good for everything. comes in aerosol or by the gallon.

Most hardware stores carry it.

Bud from Port Hardy